The Muse may be a physically small project for Graham Construction, a US$1 million transformation of a century-old timber-company’s offices into an upscale craft coffee house and speakeasy-style whiskey bar on the waterfront in Everett, Washington. But the lovely 6,000-square-foot building, which features nearly every kind of wood cut and milled in the Pacific Northwest, has played an outsized roll in demonstrating an innovative technology combination – newly applied to a construction environment – that promises to increase quality of work, save time and money, and improve the construction experience for building owners.

The Muse Whiskey and Coffee Bar – Everett, Washington USA

Michael Nesvik joined Graham’s Seattle Buildings office in 2018 with a mandate to find any technology that might help the team do things better or faster, assist in gaining projects, improve Graham’s preconstruction service offering, or accelerate the company’s use of Building Information Modelling (BIM). The particular technology Nesvik identified and recently pioneered at the Muse is called MatterPort. MatterPort produces high-resolution and measurable scans which, when married to a comparison tool, enables the company, subcontractors, and clients to effectively “see through” walls to know what lies beneath the skin.

The inexpensive solution is proving itself capable of sharpening the accuracy and lowering the costs of mechanical, electrical, and plumbing (MEP) rework while strengthening the confidence of clients and inspectors. “We’re using MatterPort through all stages of construction,” Nesvik says. Since pioneering MatterPort at Everett, Graham has used it all over Washington and in the Vancouver area.

MatterPort’s 360-degree walk-throughs have made it a staple in residential real estate marketing for years. “It’s a really cool way to show off a building,” says Nesvik. Several people at Graham had begun talking about using MatterPort to showcase finished projects for individuals who might not be able to attend in person. Last year Nesvik, the Seattle Buildings team’s Construction Technologies Engineer, performed a series of test scans at a recently completed Tribal School in La Push, Washington.

Impressed by MatterPort’s simplicity and ease of use, Nesvik realized the technology might be suitable for scanning a building’s interior at the final MEP rough-in stage of construction. Gaining an accurate record just before walls are clad is important, but the construction industry has struggled to find the best solution. Especially in the commercial and multi-family residential construction the Seattle Buildings team specializes in, typically there’s very little time between when all MEP systems are entirely complete and when crews start affixing drywall.

Construction companies often opt to snap as many digital photos as possible in the brief time. But such imagery is neither searchable nor measurable. A tradesperson going in perform rework must typically cut out a section of wall to locate the item in question – perhaps a missed valve, a leaking joint, or checking whether backing needed to support a shower bar was installed. “This kind of rework gets expensive and time-consuming, especially if you don’t know where things are and you have to cut out a large wall area and re-do everything,” notes Nesvik.

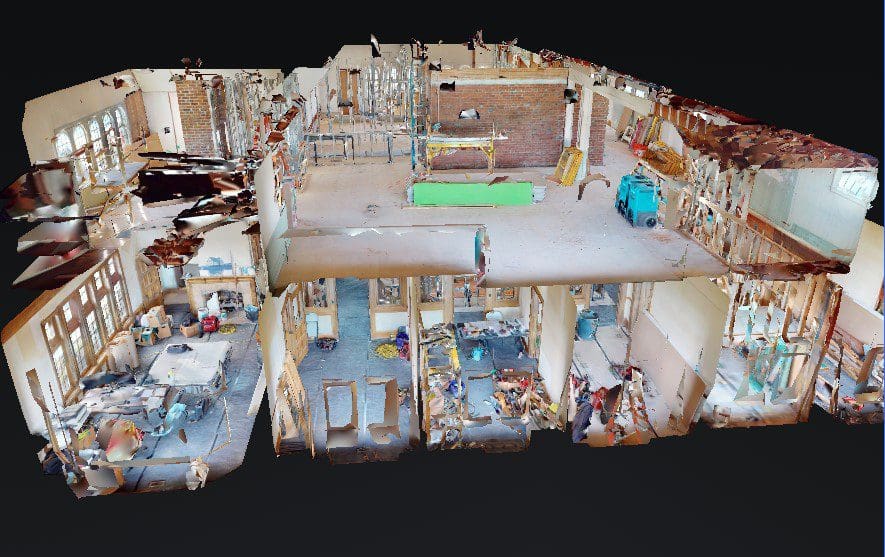

Post Rough-in Modeling

A major improvement came with OpenSpace, a helmet-mounted video camera that facilitates rapid walk-throughs at multiple construction stages. OpenSpace creates a credible record, is searchable, and allows addition of instructions and notes between project participants. Graham uses OpenSpace extensively (as described in articles ‘Innovation with Purpose‘ and ‘OpenSpace Technology‘). OpenSpace does not, however, provide measurability. Notes Nesvik: “If you’re going to cut into a wall to expose a pipe or wiring, you want to know its exact location.”

Filling that capability gap is what makes MatterPort so powerful. Though it’s not as lightning-quick as OpenSpace, it’s far more than just a camera, not only taking high-resolution visual images but conducting a 360-degree, three-dimensional LiDAR scan, producing a PointCloud rendering of an entire building. “You can label and do callouts, allowing the user to go to a particular room or other location with a search and click,” says Nesvik. “And it’s measurable, so the user knows exactly where everything is behind the walls.” LiDAR is the key ingredient.

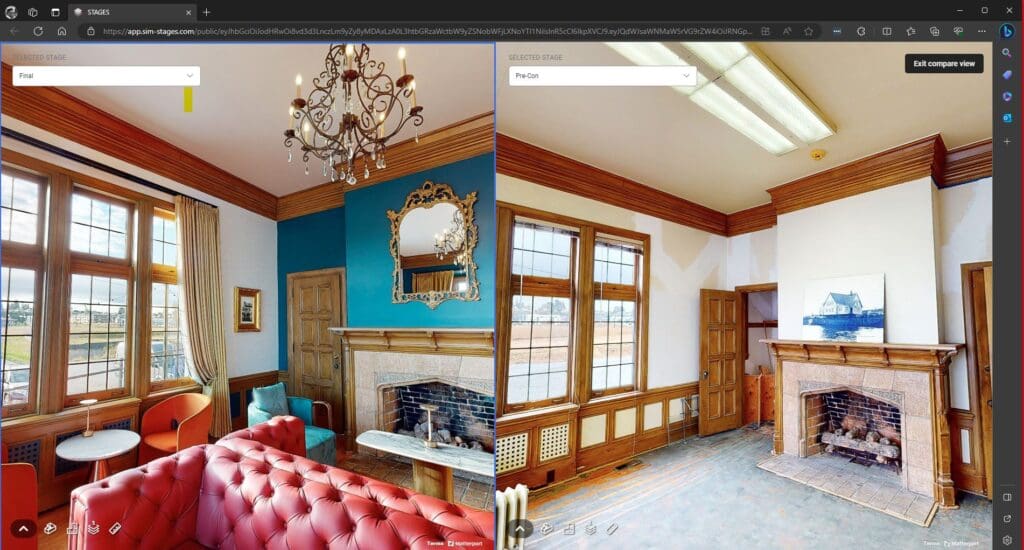

Nesvik became further intrigued by a comparison tool created by a partner company of MatterPort’s. Combining scans from different stages creates a digital walk-through allowing users to effectively look through the walls. “This means the tradesperson is seeing exactly where they are and where they want to get to, to expose for any repairs or rework,” says Nesvik.

The LiDAR scanning aspect also opens a window to a truly remarkable capability: making the capturing of spaces in light or dark areas extremely accurate within less than an inch. This accuracy can create an exact floor plan and reflected ceiling plan within 48 hours, all done through MatterPort. This is especially useful when renovating an older building whose drawings are long-lost and, in any case, whose current state “as built” departs greatly from any drawings. An early scan can thereby produce as-built pre-reno drawings. The capability also facilitates rendering “as built” drawings after completion, since the result may differ from new design drawings. “We can create a floorplan of the building for, like, $15,” Nesvik enthuses. The results even are precise enough for use as baseline drawings by project architects/designers.

Tradespersons are seeing exactly where they are and where they want to get to, to expose for any repairs or rework,

At the Muse, Nesvik scanned the entire two-storey building in about three hours. He used MatterPort before construction began, at the MEP finish stage, and after project completion “to showcase how beautiful the building is.” The first scan created a digital footprint of the existing building, which increased the confidence of the building’s owner and neighbour that nothing would be damaged during renovation. “The Muse became our full-fledged test case for MatterPort,” Nesvik says.

The Paramount – Richmond, BC

The Seattle Buildings team aren’t the only ones excited by MatterPort. Graham has used it for a high school renovation in Couer d’Alene, Idaho, renovations, and at the University of Idaho in Moscow. Graham’s Vancouver office has also dived in, using MatterPort on several projects, including a 40-storey high rise tower in downtown Vancouver, several areas of the Paramount complex, and multiple scans in portions of the Vancouver General Hospital reno, where it is being used for overlay of BIM 3D models to facilitate coordination with subcontractors and safety procedures.

Walk through The Muse using Matterport and test the features, including ‘compare view’.